- ABOUT US

- NEWS

-

PRODUCTS

Flat Bed CNC Lathe

SN SERIES Flat Bed CNC Lathe

MN SERIES Flat Bed CNC Lathe

BN SERIES Flat Bed CNC Lathe

GN SERIES CNC Facing Lathe

FBN SERIES CNC Facing Lathe

FBN-B SERIES Flat Bed CNC Lathe

GHN SERIES Flat Bed CNC Lathe

Flat Bed CNC Lathe

SN SERIESElevate your precision and performance with Key East's SN Series, the premier choice for compact flat-bed CNC lathe machines. Achieve exceptional results with high spindle speeds, adjustable center distances, and robust construction. Perfect for high-speed turning operations.

VIEW MORE Flat Bed CNC Lathe

Flat Bed CNC Lathe

MN SERIESDiscover CNC machining excellence with Key East's MN Series, the medium-sized flat-bed CNC turning solution. Versatile, precise, and user-friendly, it's your top choice for efficient and accurate machining. Customize it to meet your needs and redefine precision.

VIEW MORE Flat Bed CNC Lathe

Flat Bed CNC Lathe

BN SERIESElevate precision machining with Key East's BN Series, designed for heavy-duty work. Engineered with advanced control systems, robust construction, and a one-piece bed casting, it delivers exceptional accuracy and efficient material removal. Customize for your unique requirements and tackle large workpieces with ease.

VIEW MORE Flat Bed CNC Lathe

Flat Bed CNC Lathe

GN SERIESElevate productivity with Key East's GN Series, one of our largest flat-bed CNC lathes. Tailor configurations, harness cutting-edge control systems, and enjoy unbeatable rigidity and stability. Ideal for high-performance machining, especially on substantial workpieces.

VIEW MORE CNC Facing Lathe

CNC Facing Lathe

FBN SERIESDiscover precision machining like never before with our FBN Series. These facing lathes offer unmatched accuracy and versatility. The FBN Series by Key East Machinery delivers precision machining excellence. Explore its features and capabilities.

VIEW MORE CNC Facing Lathe

CNC Facing Lathe

FBN-B SERIESThe FBN-B Series is your gateway to precision machining at its best. Explore its versatile features for machining excellence. Precision machining excellence is here. The FBN-B Series delivers high performance and an extended reach for your machining needs.

VIEW MORE Flat Bed CNC Lathe

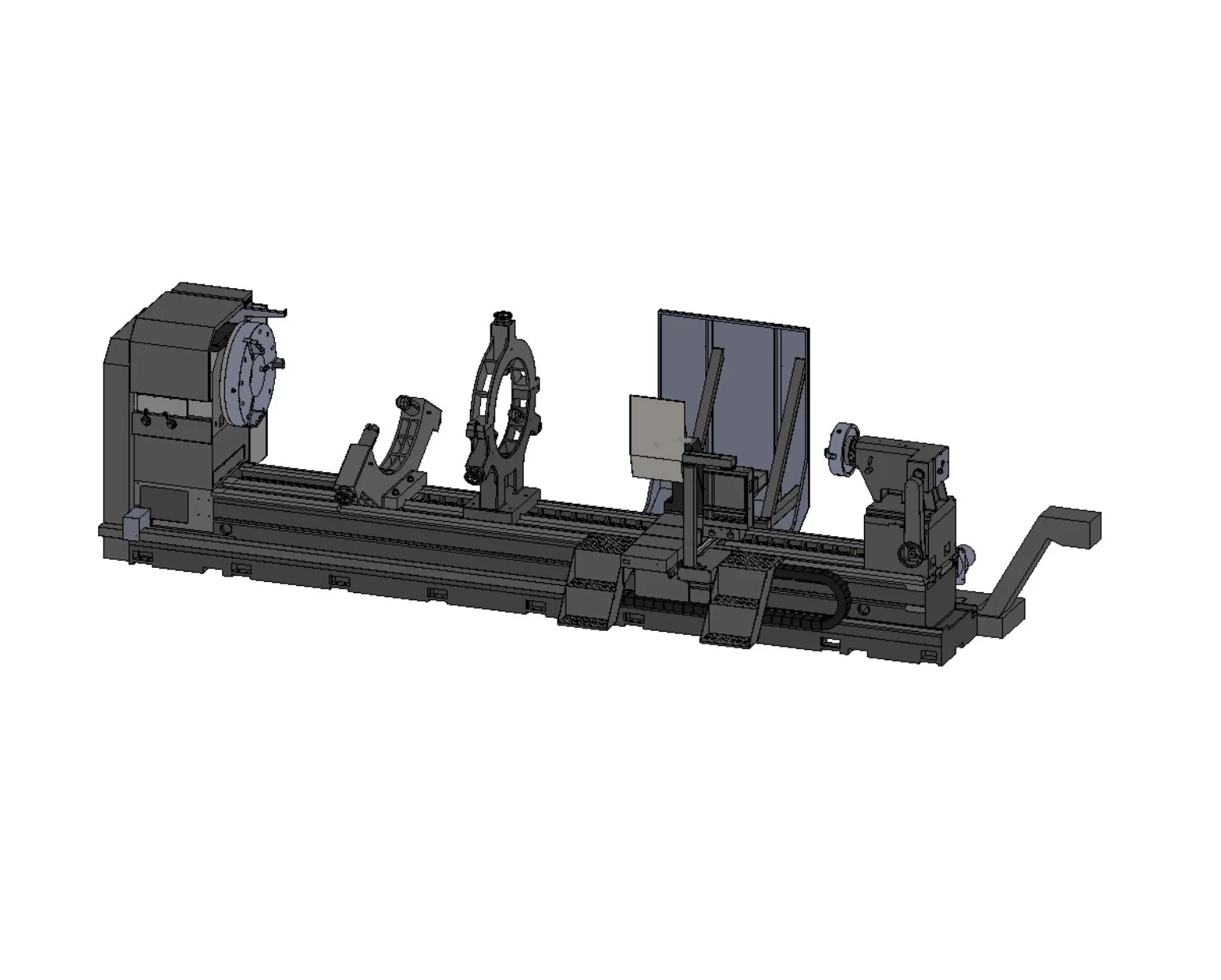

Flat Bed CNC Lathe

GHN SERIESEnhance Heavy-Duty Machining with GHN Series. Experience Superior Efficiency and Precision. Key East Machinery's 5-Bed Way Flat Bed CNC Lathe - Your Path to Excellence.

VIEW MORE Flat Bed Lathe

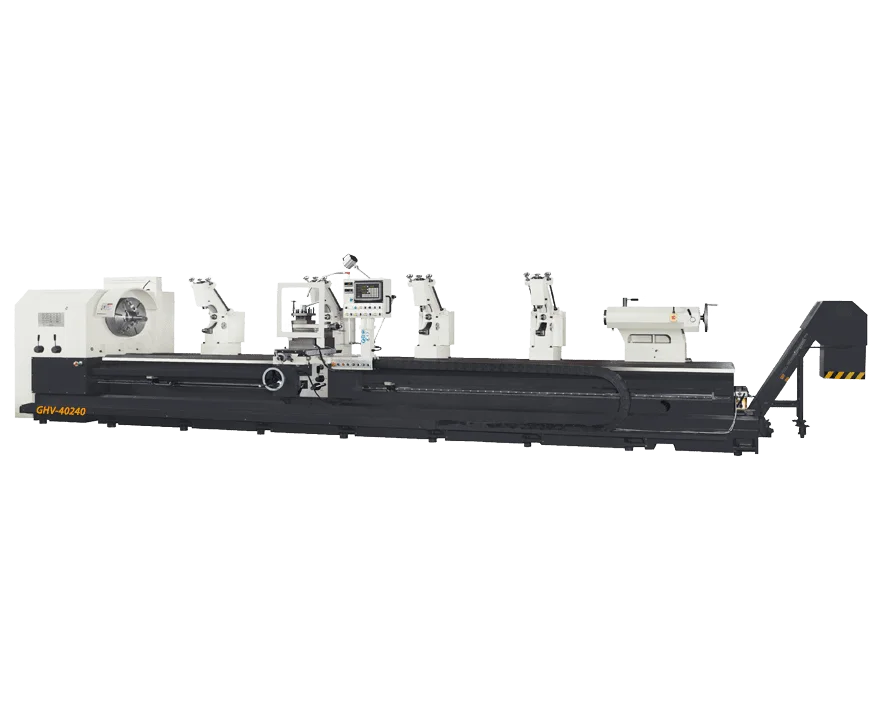

Flat Bed Lathe

GHV SERIESExplore Key East Machinery's Conventional Flat Bed Lathes, meticulously designed for precision machining. Discover stability, versatility, and durability for your manufacturing needs.

VIEW MORE COMBO MACHINE

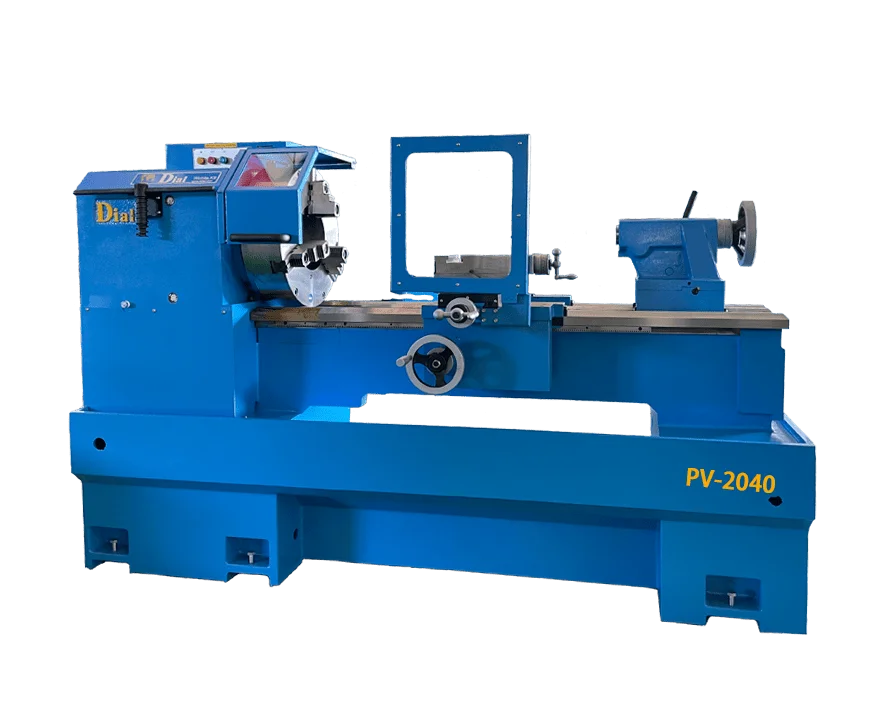

COMBO MACHINE

PV SERIESTailored for unique requirements, the PV Series offers precision in cutting pipes and automobile transmission shafts. Explore specialized machining solutions.

VIEW MORE COMBO MACHINE

COMBO MACHINE

PVA-SERIESDiscover the PVA Series, where precision meets versatility in cutting pipes and transmission shafts. Auto feeding and threading at its best.

VIEW MORE - MEDIA

- CONTACT US